Last June in Turin, Iveco Group celebrated its 50th anniversary by reflecting on its history and taking stock of current and future technologies. A highlight of the event was the unveiling of new FPT Industrial engines—a brand of Iveco Group—including the Xcursor 13, presented in its hydrogen-powered version

Titled “50xBeyond”, the event was held at the OGR in Turin (the former Officine Grandi Riparazioni) and marked five decades since the group’s founding in 1975. Today, Iveco Group is navigating a highly complex era in transportation, developing innovative solutions for both people and goods mobility. While traditional propulsion systems are expected to remain dominant for the foreseeable future, it’s also clear they’ll gradually give way to alternative technologies. However, these new technologies—ranging from battery- or fuel cell-powered electric vehicles to internal combustion engines using alternative fuels—still present a range of uncertain possibilities.

During the celebration, CEO Olof Persson emphasized the challenges a vehicle and engine manufacturer faces when planning future design and commercial strategies. The biggest obstacles are not in the present, but in the undefined future, where performance, environmental, and operational requirements remain largely unclear. This means navigating uncharted waters while preserving the company’s enduring “spirit in motion,” which has guided Iveco Group through its transformation from the 1975 merger of Fiat Veicoli Industriali, Unic, and Magirus-Deutz into a multinational corporation with seven brands, 36,000 employees, 19 production plants, and 30 R&D centers.

These very R&D centers allowed the event to blend historical celebration with industrial innovation, most notably through the world premiere of three new battery-electric vehicles aimed at redefining transport efficiency across heavy- and light-duty applications, and potentially leading Iveco’s electrification efforts.

At the forefront stood the S-eWay, a 4×2 long-haul electric truck with a range of up to 600 km. Alongside it were two light commercial vehicles—eJolly and eSuper Jolly—developed in collaboration with Stellantis and integrated into the Daily family.

The fully electric S-Way truck directly addresses the electrification goals for long-distance freight transport. It features a next-generation lithium iron phosphate battery pack with a usable capacity of 603 kWh, with 97% usable energy. These batteries are guaranteed for 10 years or up to 1.2 million kilometers. The truck offers continuous power output of 480 kW, with charging times from 20% to 80% in just 60 minutes via 350 kW DC fast chargers. While this vehicle is currently suitable only for specific applications, broader deployment awaits the development of charging infrastructure.

Its high-performance battery pack operates efficiently across a wide temperature range—from -30°C to +45°C—and is supported by an aerodynamically optimized cab that contributes to greater efficiency. The cab is longer than category standards but maintains compatibility with current trailers and steering geometry. A notable design element includes a 9-ton capacity pneumatic front suspension axle and a wheelbase of 3,932 mm, which enable optimal weight distribution and room for large battery packs without sacrificing maneuverability.

FPT Industrial plays a central role in powering the S-eWay and other current and future Iveco vehicles. The S-eWay is equipped with the eAx 840-R electric axle, delivering 840 kW (1,142 hp) of peak power and 45,000 Nm of peak torque. This is FPT Industrial’s top-tier electrified axle, suitable for vehicles with a gross weight up to 44 tons. It includes two integrated electric motors with over 92% efficiency and a single-speed transmission, all within a compact frame: 1,244 mm wide, 641 mm high, and weighing 1,360 kg.

In addition to heavy-duty axles, FPT also showcased its new compact eAx 200-R axles for vehicles up to 11 tons. These axles feature a single integrated electric motor, single-speed transmission, and operate at 800 volts—providing higher efficiency than lower-voltage competitors. They offer up to 200 kW (272 hp) of power and 10,000 Nm of torque, all in a reduced-size, lightweight package.ù

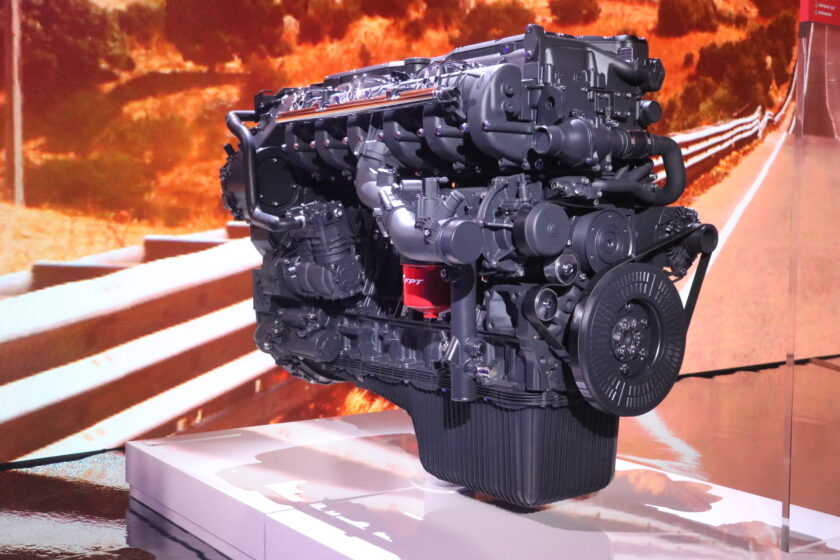

FPT Industrial also presented its forward-looking propulsion technologies, including the hydrogen version of its next-generation Xcursor 13 (Xc13) engine, currently in operational testing in Prinoth h2Motion hydrogen-powered snow groomers. This 12.9-liter inline-six engine was designed for modular, multi-fuel applications, sharing the same base and subsystems across versions, with only the cylinder head and a few components differing between fuel types.

In its hydrogen configuration, it uses a spark-ignition system with a central spark plug along the cylinder axis and direct injection, producing 520 hp and 2,500 Nm of torque. The engine runs on ultra-lean air-fuel mixtures, with stoichiometric ratios of about 34:1, reaching up to 85:1, significantly reducing NOx emissions.

Despite the advanced combustion technology, the engine retains FPT’s hallmark durability and reliability, aided by the use of compacted graphite iron (CGI), which reduces engine block weight and contributes to a 10% overall weight reduction compared to previous-generation engines.

With these developments, FPT Industrial and Iveco Group continue to balance innovation and legacy, steering boldly into the future while staying grounded in the robust engineering that has defined their past 50 years.

Title: Iveco Group, spirit in motion

Translation with ChatGPT