Founded in 2005 by a diverse group of aerospace engineers, writers, and volunteers, Interstellar Technologies is a Japanese company established in 2019 and located on the island of Hokkaido. It was the first to launch a private carrier rocket capable of reaching space, a milestone achieved in 2021 and repeated twice thereafter. Now advancing further, the company focuses on developing new technologies to accelerate human activities in space, with a keen eye on environmental considerations.

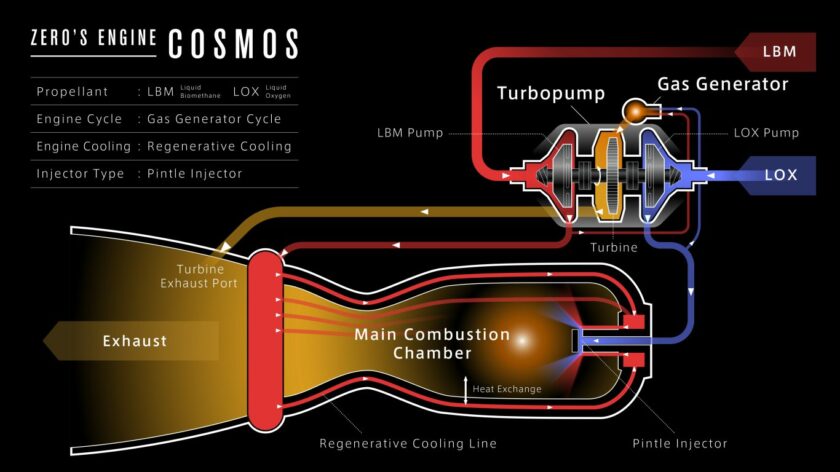

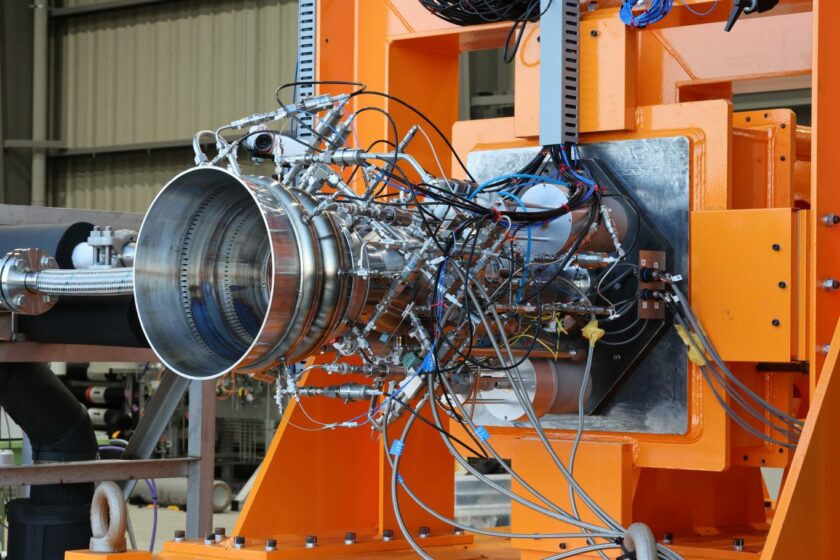

Among the most intriguing research areas is propulsion systems, with the “Cosmos” project standing out. This initiative aims to equip future space carriers, named “Zero,” with engines powered by liquid biometane. Initial static tests of this solution, successfully conducted at the Hokkaido Spaceport complex in Taiki at the end of last December, demonstrated the viability of using locally sourced livestock manure as a sustainable fuel source for missile production.

Local farmers actively collaborated in the project by processing the collected manure with specialized equipment to extract biogas, which was then converted into liquid biometane by the company Air Water for use in the “Zero” propulsion system. This process enables cost-effective missile fuel production while ensuring the necessary performance for mission profiles. It’s a progression akin to the adoption of liquid methane in the space industry’s propulsion sector. Interstellar Technologies has developed a specially designed combustion chamber for using biometane, integrated into a dual-stage open-cycle engine architecture. In this setup, the fuel and oxidizer are injected through a single injector into the main combustion chamber, with the fuel circulated at high pressure around the chamber walls and nozzle for cooling, following a regenerative cooling scheme. This solution maximizes performance while preventing overheating.

Regarding the injection system, known as a “pintle injector” and already employed in SpaceX vehicles, the use of a single-hole injector allows for significant cost savings compared to the multi-hole injectors typically used in liquid bipropellant engines. Although such a solution generally reduces unit performance, developments by the University of Tokyo in collaboration with Jaxa Space Innovation researchers have led to a new design improving and enhancing combustion performance. Currently, these developments have resulted in engines capable of providing thrusts of around 60,000 newtons, paving the way for the development of units with an operational thrust of 130,000 newtons.

The turbopump also supplies power to hydraulic actuators, while the nozzle works to control the carrier’s roll. The development of “Zero” aims to offer a new space carrier for launching small satellites from 2025 in Asia and Oceania, with costs approximately one-tenth lower than current figures, estimated by the company to be around five million euros per launch. The “Zero” carrier will stand at 32 meters in height with a diameter just under two and a half meters, weighing a total of 71 tonnes, carrying a payload ranging from 250 to 800 kilograms depending on the target orbital distance. The carrier will feature a dual-stage configuration, with the first stage supported by nine engines and the second stage equipped with a single engine.

Title: Interstellar “Cosmos”, innovation “Made in Japan”

Traslation with ChatGPT